Hello friends, Today we are going to talk about marking tools or marking out tools which are widely used in industries.

There are so many types of marking tools in workshop or fitting shop, which we will know in detail one by one.

What is Marking Tool?

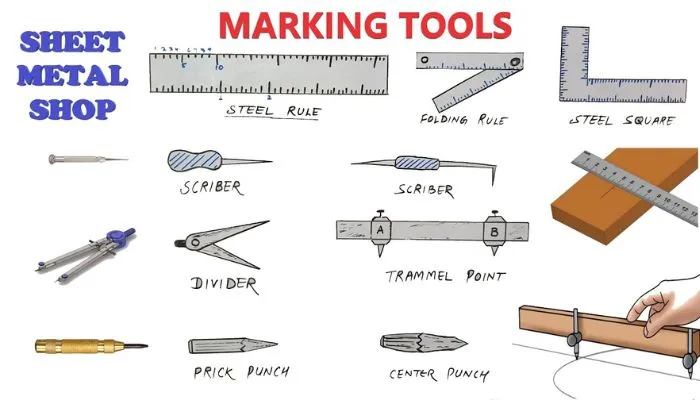

A marking tool is any instrument or device used to make marks, lines, or notations on a surface. These tools are widely used in various fields and trades for purposes such as measurement, layout, identification, and precision marking. Different types of marking tools are designed for specific applications, and they play a crucial role in ensuring accuracy and precision in various tasks.

Types of Marking Tool

There are the following types of marking tools in a workshop:

- Surface Gauge

- Surface Plate

- Marking Table

- Scriber

- Prick Punch

- Center Punch

- Divider

- Trammel

- Hermaphrodite Caliper

- ‘V‘ – Block

- Angle Plates

- Parallels

- Bevel Square

- Combination Set

In the realm of metalworking, machining, and precision engineering, a comprehensive set of tools is indispensable for achieving accuracy, consistency, and quality in the fabrication process. Each tool serves a specific purpose, contributing to the overall efficiency of the manufacturing workflow. In this exploration, we delve into the functionalities and significance of key tools commonly used in these industries.

Read also: Try Square: Parts, Types, Grades, Checking Accuracy, Uses

Surface Gauge

The surface gauge is a versatile measuring tool renowned for its ability to ensure flatness and facilitate precise height adjustments. Comprising a flat base, an upright post, and a spindle, this instrument aids in measuring variations in surface flatness and setting accurate heights for other tools and workpieces. The addition of an indicator or scriber enhances its utility in layout work, enabling the marking of lines at specific heights.

Surface Plate

A fundamental component of any precision workshop, the surface plate provides a meticulously leveled and flat surface for conducting measurements, inspections, and layout work. Typically made of granite or cast iron, its primary function is to serve as a reference point for achieving accuracy in various machining operations.

Marking Table

Dedicated to the meticulous craft of marking and layout work, the marking table is designed to provide stability and support during the precision marking of workpieces. Its flat and sturdy surface ensures that markings are executed with precision, contributing to the overall accuracy of the manufacturing process.

Scriber

A scriber is a pointed tool employed for marking lines on a workpiece. Whether attached to a surface gauge or used independently, it is instrumental in creating precise guidelines for subsequent machining or assembly processes. The scribing tool’s fine point ensures accuracy in marking, especially when dealing with intricate designs or tight tolerances.

Prick Punch

In the arsenal of a machinist, the prick punch plays a crucial role in creating small, precise marks or divots on a workpiece. These marks serve as reference points for subsequent operations such as drilling, milling, or turning, aiding in maintaining accuracy throughout the fabrication process.

Center Punch

A center punch is a tool designed to create a more pronounced indentation at the center of a marked point. This deeper mark serves as a guide for drill bits during drilling operations, ensuring that holes are precisely located and drilled with accuracy.

Divider

Dividers are essential tools for measuring and marking equal distances or dividing a line into specific increments. Whether used in layout work or pattern making, dividers contribute to the consistent replication of measurements, a critical factor in achieving uniformity in the manufacturing process.

Trammel

For tasks requiring the scribing of large arcs or circles, the trammel is the tool of choice. Comprising two points connected by a bar, the trammel provides a versatile solution for creating curves of varying radii, catering to the diverse requirements of precision work.

Hermaphrodite Caliper

The hermaphrodite caliper is a specialized measuring tool equipped with one straight leg and one bent at a right angle. This unique design allows for the measurement and marking of both inside and outside dimensions on a workpiece. Its versatility makes it a valuable asset in various machining and fabrication scenarios.

‘V’ – Block

When it comes to securely holding cylindrical workpieces for marking, inspection, or machining, the ‘V’ – block is an indispensable tool. Its design, featuring a V-shaped groove, ensures stability and precise positioning of cylindrical components, contributing to accurate and efficient manufacturing processes.

Angle Plates

In machining, angle plates are fixtures designed to securely hold workpieces at specific angles. These plates are instrumental in facilitating accurate machining operations, ensuring that workpieces are machined precisely according to the desired angles and specifications.

Parallels

Parallels, also known as parallel bars, are indispensable tools for setting the height of a workpiece above the work surface. Their flat and precise surfaces allow for consistent and accurate measurements, crucial in achieving uniformity and precision in machining operations.

Bevel Square

For tasks requiring the measurement and marking of angles, the bevel square is an invaluable tool. Used in both woodworking and metalworking, it provides a reliable means of achieving accurate angle measurements, contributing to the overall precision of the fabrication process.

Combination Set

A combination set is a comprehensive toolset that includes various measuring and marking instruments. Typically comprising a combination square, protractor, and level, this set is a versatile solution for diverse measurement and layout requirements. Its multifunctionality makes it a go-to tool for machinists and fabricators seeking efficiency and accuracy in their work.

In conclusion, the tools mentioned above represent a curated selection of essential instruments that form the backbone of precision metalworking and machining. Each tool, with its unique features and functionalities, contributes to the overall goal of achieving accuracy, consistency, and quality in the manufacturing process. As technological advancements continue to shape the industry, these timeless tools remain integral to the craft, embodying the meticulous craftsmanship that defines the world of precision engineering.

Read also: Are PET Bottles Safe for us and the environment?

If any doubt you can ask me through a comment or direct mail to me.