Hello everyone, today’s topic revolves around fasteners and their diverse applications in various industries. Fasteners play a crucial role in joining different parts together securely, whether for temporary or permanent purposes. Let’s delve deeper into the world of fasteners to understand their types and uses.

Fasteners are integral components used across industries to join parts together efficiently. They facilitate the assembly and disassembly of machine parts, allowing for maintenance, repair, and modification as needed.

In the realm of machines like lathes and drilling machines, some parts require permanent fixation, while others need to be easily detachable for maintenance or adjustment purposes. Fasteners serve this purpose by securely holding components together while also enabling their convenient disassembly when necessary.

Such as Lathe machines, Drilling machines, and much more.

Different types of Fasteners

Generally, Fasteners can be divided into three categories:

- Temporary Fasteners

- Semi-permanent Fasteners

- Permanent Fasteners

Temporary Fasteners

These fasteners facilitate the easy unfastening of connected parts without causing damage to the components.

Some components are used for temporary Fastening which is as follows:

- Bolt

- Screw

- Nuts

- Washer

- Stud

- Pin

- Keys

See in figure different types of temporary fasteners which are described below in detail.

Bolt

A bolt features a solid head at one end and a threaded portion at the other, where a washer and nut are placed to fasten it securely.

Key types of bolts include hexagonal-headed bolts, square-headed bolts, round bolts, cylindrical or cheese-headed bolts, T-headed bolts, eye bolts, hook bolts, foundation bolts, and countersunk-headed bolts.

Bolts are primarily employed to join one flange to another, machine parts, and similar applications.

Screw

A screw is a type of fastener typically employed to join thin sheets or metals together.

Common tools like screwdrivers and wrenches are utilized to tighten screws.

Screws come in various types based on their shape and usage, including cap screws, collar screws, shoulder screws, and others.

Nuts

A nut is a component utilized with a bolt or stud bolt to temporarily join and tighten two or more parts together.

It serves as a specialized piece designed to secure the bolt in place.

Common types of nuts include hexagonal nuts, square nuts, flange nuts, wing nuts, capstan nuts, ring nuts, knurled nuts, prevailing torque nuts, and others.

Note: Bolts and nuts are typically loosened and tightened using various types of spanners.

Washer

A nut is a component utilized with a bolt or stud bolt to temporarily join and tighten two or more parts together.

It serves as a specialized piece designed to secure the bolt in place.

Common types of nuts include hexagonal nuts, square nuts, flange nuts, wing nuts, capstan nuts, ring nuts, knurled nuts, prevailing torque nuts, and others.

Note: Bolts and nuts are typically loosened and tightened using various types of spanners.

Washer

A washer is positioned between a bolt and nut to provide a smooth bearing surface, thereby increasing the contact area and reducing the load between the bolt and nut.

Additionally, the washer prevents the nut from embedding into the metal, enabling tighter tightening of the nut.

Stud

A stud resembles a screw but lacks a head.

Studs are employed in areas where components are frequently assembled or disassembled.

Different types of studs include plain studs, collared studs, square cross-section plain studs, and hexagonal socket head studs.

Pin

A pin typically refers to a rounded metal piece that connects two separate, hinged objects.

Various types of pins include solid pins, hollow pins, split pins, gudgeon pins, and dowel pins, among others.

Keys

Keys are utilized to secure pulleys or gears onto a shaft and inhibit any relative movement between them.

They can be removed as needed to engage the mating components.

Keys are categorized into two types based on their fitting: sunk keys and saddle keys.

Semi-permanent Fasteners

All fastening methods, where the fastener may sustain damage but not the job, fall under this category.

These methods are employed when there’s minimal likelihood of needing to reopen the joints, such as in soldering or riveting.

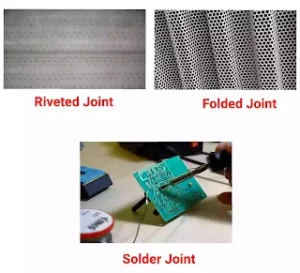

Semi-permanent fastener joints can be classified into three parts as follows:

- Riveted Joint

- Folded Joint

- Solder Joint

See in the figure all different types of semi-permanent fasteners which are described below in detail.

Riveted Joint

A riveted joint is utilized for joining materials like sheets or plates.

In riveted joints, drilling or punching methods are employed to join the sheets or plates.

- Lap Joint

- Butt Joint

- Caulking and Fullering of Riveted Joint

Lap Joint

In the lap joining method, sheets or plates are joined by overlapping the two surfaces.

The lap joint can be divided into two parts.

- Single row lap joint

- Double row lap joint

Butt Joint

An additional sheet is used to join both of the plates or sheets being joined.

Caulking and Fullering of Riveted Joint

Caulking and fullering of a riveted joint is a method used to create leak-proof joints with high efficiency. This process involves hammering the joints manually or with a power hammer and using a fullering tool to spread the ends.

Such joints are commonly utilized in steam boilers, air tanks, and water storage tanks.

Folded Joint

With this method, thin metal sheets or plates are effectively joined. These joints find application in assembling boxes, tubs, crockery, and similar items.

Solder Joint

Soldering, an age-old technique, is employed for creating joints, especially for lightweight applications. It involves the use of solder, an alloy typically composed of tin and lead. The melting point of solder typically ranges from 135 to 325°C.

Permanent Fasteners

This process is employed when there is no intention of reopening the joints. Disassembling such joints results in damage to both the job and the fastener. Examples include welding, brazing, etc.

- Brazing

- Welding

Brazing

This method is similar to soldering but results in stronger joints. Known as hard soldering, it primarily consists of copper and zinc. Sometimes, silver is added to enhance the brazing quality.

Welding

Welding is the process of joining two or more metal parts by melting them to the point of fusion. Pressure may be applied depending on the requirement.

Welding is classified into the following parts

- Plastic or Pressure Welding

- Fusion or Non- pressure Welding

Plastic or Pressure Welding

In this process, the ends to be joined are heated to their melting point, and pressure is applied to fuse them together. Filler metal may be used as needed.

Fusion Welding

This welding method is also referred to as non-pressure welding. In this process, metals are heated to their melting point without the need for applied pressure.

Assembly Techniques

Assembly technique refers to the amalgamation of methods employed for assembling machines, their components, and equipment. Assembling entails the process of joining various parts of a machine together to create a unified unit.

The various types of assembly techniques are discussed below:

- Aligning

- Bending

- Sealing

- Fixing

- Thread Cutting

- Jointing

Aligning

Alignment is a procedure involving the arrangement of components in a straight line to enhance the accuracy of work. Typically, it is crucial for the shafts in machines because without proper alignment, machine shafts may not function effectively.

Bending

Bending refers to the process wherein an object changes its shape from straight to curved or angular, or vice versa, when force is applied at a specific point or part of the object.

Sealing

A mechanical seal is a device employed in machinery or equipment to prevent leakage.

Typically, these seals are utilized in rotating equipment such as pumps, mixers, blowers, and compressors.

A mechanical seal must consist of four functional components, which are as follows.

- Primary Sealing Surface

- Secondary Sealing Surface

- Actuation

- Drive

Fixing

When a job needs to be held securely in place for a specific duration, the fixing process is employed.

During fixing, a workpiece is tightly secured to facilitate an operation.

For example, a fixture is utilized to secure the job, designed according to the shape of the worktable and the job itself.

Thread Cutting

Thread cutting is a method used to create grooves around a cylinder, bolts, studs, and similar components.

This process involves making successive light cuts using a thread cutting tool bit designed to match the shape of the thread form.

Jointing

Jointing is a crucial process employed to connect two parts of a machine or structure securely, allowing for both assembly and disassembly as needed.

Through jointing, mechanical components can be effectively assembled with each other, ensuring stability and functionality.

I trust that you now have a clear understanding of various types of fasteners and their applications, as well as gained insights into assembly techniques.

FAQ for Fasteners

How many types of fasteners are there?

Fasteners are categorized into three main types: temporary fasteners, semi-permanent fasteners, and permanent fasteners. These categories encompass various types such as bolts, nuts, screws, rivets, soldered joints, and welding.

Which process is not considered a temporary fastening method?

Riveted joints, folded joints, soldering, welding, and brazing are not temporary fastening processes. They are used when a more permanent attachment is required.

What is the difference between temporary and permanent fasteners?

Temporary fasteners allow for easy disassembly without damaging the connected parts, while permanent fastening methods are intended for joints that do not need to be reopened.

Which fastener is considered semi-permanent?

Rivet joints, solder joints, and folded joints are examples of semi-permanent fasteners. They offer a balance between temporary and permanent attachment methods.

Which fasteners are classified as temporary?

Temporary fasteners include nuts, bolts, washers, screws, studs, pins, keys, etc. These fasteners enable parts to be securely joined and later disassembled without causing damage.

Which fasteners are considered permanent?

Welding and brazing are classified as permanent fasteners. These methods create strong joints that are not intended to be reopened without damaging the components involved.