Hey everyone, today I’m going to talk about common industrial or workshop vices.

In this discussion, we’ll explore the various types of vices commonly utilized in workshops, as well as delve into the functionality and use of clamp devices.

Vices play a crucial role in workshops by securely holding tools or workpieces during various operations such as drilling, filing, tapping, grinding, milling, and more.

These operations are typically conducted on specific machines utilizing cutting tools like drill bits or grinding wheels.

In the production of cutting tools, a variety of materials are employed, each chosen for its mechanical properties such as high strength and hardness. Common materials include carbon steel, high-speed steel, and others, ensuring the tools meet the necessary durability and performance standards.

So, let’s get started to know the types of vices used in workshops.

What is Vice?

A vice is a fundamental tool used for holding workpieces securely in a workshop. It provides a stable grip, ensuring the workpiece remains in place during various operations such as filing, cutting, drilling, tapping, and dyeing.

Types of Vices

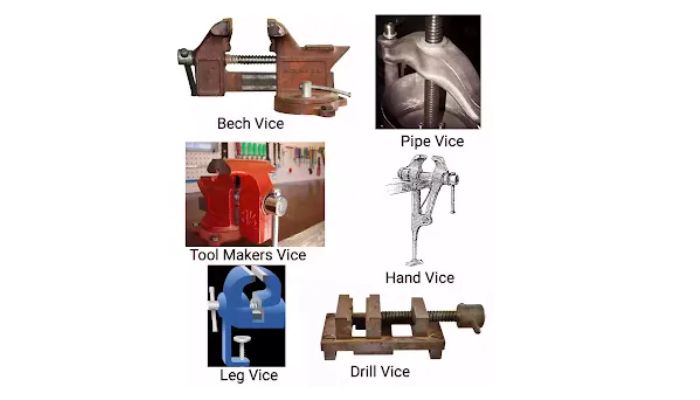

There are the following types of vices used in the workshop:

- Bench Vice

- Pipe Vice

- Tool Makers Vice

- Hand Vice

- Leg Vice

- Drill vice

- Pin Vice

Bench Vice

This tool is commonly used in workshops to secure workpieces during tasks such as sawing, filing, chipping, tapping, and external threading.

Mounted on top of a workbench, it features two hardened steel jaws with grooves for enhanced grip.

Typically adjusted to match the height of the artisan’s elbow, its body is typically constructed from cast iron or steel.

Sizing is based on the width of the jaws, and while the fixed jaw remains stationary, only the movable jaw adjusts to tighten the workpiece when the spindle is tightened.

Types of Cutting Tool Materials and Their Properties

For delicate finishing work, it’s advisable to coat the jaws with materials like aluminum, brass, or copper to protect the workpiece’s surface.

When installed on a machine, it’s referred to as a machine vice.

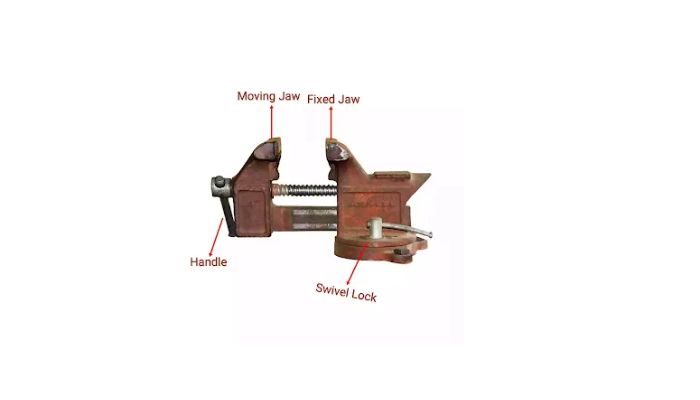

Bench Vice Parts and Functions

There are following parts are attached to the bench vice:

- Fixed Jaw

- Movable Jaw

- Jaw Plates

- Spindle

- Handle

- Box Nut

Fixed Jaw

The fixed jaw is permanently affixed to the bench using a nut and bolt assembly.

Typically constructed from grey cast iron, the fixed jaw remains stationary during operations.

Movable Jaw

The movable jaw adjusts back and forth based on the size of the workpiece.

Constructed from grey cast iron, the movable jaw provides flexibility during operations.

Jaw plates

The component inside the jaw, secured by a screw, is called a jaw plate.

These plates feature cross-cuts that enhance their grip on the workpiece.

Carbon steel is the material typically used to manufacture these plates.

Manufacturing Process of Steel: 6 Methods of Making Steel

Spindle

The movable jaw includes a spindle made of mild steel.

Movement of the movable jaw occurs solely through rotation of this spindle.

Handle

The handle is attached to the spindle and can be rotated clockwise or counterclockwise to move the spindle forward or backward.

Typically, the handle is constructed from mild steel.

Box Nut

The nut through which the spindle passes is referred to as both the box nut and the guide nut.

The box nut is always positioned within the fixed jaw and is typically made of cast iron or gun metal.

Points to be Noted While Fixing a Bench Vice

- The height of the vice should be either one meter from the shop floor to the top of the vice or adjusted to match the artisan’s elbow height.

- It’s recommended to securely fasten the bench vice using bolts, nuts, and washers above the bench surface for optimal support and stability.

- The vice should be positioned level and parallel to both the workbench and shop floor. Misalignment may cause uneven rubbing of materials on the workpiece.

- The fixed jaw of the vice should slightly protrude from the edge of the workbench.

- Ensuring the vice is firmly secured is crucial. Any instability may result in vibration, affecting surface finish and precision.

Pipe Vice

This type of vice is commonly utilized for working with round-shaped objects and for C-clamping pipes, particularly in plumbing and locksmith tasks.

The jaw of this vice features a V-shaped groove, designed to securely grip pipes and cylindrical bars during cutting, threading, and similar operations.

It’s typically positioned securely at the end of the bench for convenience.

Tool Makers Vice

This particular type of vice is employed for securing small, intricate workpieces during filing and machining tasks.

It possesses the ability to swivel, allowing the workpiece to be positioned at various angles as needed.

Hand Vice

This type of vice is utilized for grasping screws, rivets, nails, and similar small materials that are challenging to hold in a bench vice.

Occasionally, it’s also employed for securing thin plates during drilling operations.

Leg Vice

This particular vice is employed for heavy-duty and rugged tasks like bending, forging, and chiseling, capable of handling substantial workloads.

Drill vice

This sturdy vice features a movable joint that allows it to be adjusted forward and backward by turning the handle of the movable jaw.

It’s commonly employed for drilling operations on small workpieces.

Pin Vice

This type of vice is utilized for securing small-diameter workpieces such as pins, needles, and similar objects.

Care and Maintenance of Vices

- Avoid using the sliding back as an anvil; tighten the vice solely by its handle. Refrain from using a hammer to increase leverage.

- Periodically clean the vice and check for any looseness. If the jaws become loose, replace them as needed.

- When the vice is not in use, keep it loosened.

Clamp Devices

Clamp devices are also used to hold the tool or a job.

There are the following types of clamp devices found:

- Vice Clamps

- “C” Clamp

- Tool Makers Clamp

Vice Clamps

Employing these soft jaws prevents marking on the vice jaws and maintains the workpiece’s finish.

These jaws come in various sizes depending on their intended use.

They are crafted from soft materials such as copper, lead, aluminum, tin plate, etc., to protect the workpiece being held.

“C” Clamp

This clamp is a versatile tool commonly utilized for various straightforward tasks. Its design features a frame resembling the letter ‘C’ in English, along with a screw mechanism.

It’s employed for securing workpieces on an angle plate or drill machine table, as well as for holding multiple workpieces together. It’s crucial to select an appropriately sized ‘C’ clamp for each specific job.

Avoid applying excessive pressure, as this could lead to the screw rod turning unexpectedly.

Tool Makers Clamp

This clamp is also known as a parallel clamp and is typically crafted from mild steel. It’s employed for securing small pieces together during assembly, marking, machining, drilling, riveting, screwing, and similar tasks.

Available in sizes ranging from 50 to 150 mm, these clamps feature long jaws. Additionally, a clip is affixed to the screw via screws to prevent it from dislodging while adjusting.

With this information, you should now have a good understanding of the various types of vices and clamp devices commonly used in workshops.

Types of Taper Turning Methods on Lathe Machine

Su kaçağı bulma Su kaçağı sorunumu tespit etmek için Şişli su kaçağı tespit ekibine güvendim ve doğru bir tercih yaptığımı gördüm. blog/67421

Şişli tıkanıklık açma fiyat teklifi Su tesisatı sorunlarınızı çözmek için tercih edebileceğiniz en iyi firma Şişli su tesisatçısı.

Ümraniye da profesyonel tesisat hizmetleri Ümraniye da lavabo tıkanıklığı için bu firma ile çalışmak harikaydı. Ekip, sorunumuzu hızlıca ele aldı ve sonuca odaklanarak etkili bir çözüm getirdi.Kesinlikle memnun kaldık!

Klozet açma Ümraniye Kanalizasyon borularımız tıkandığında, bu firma ile iletişime geçtik ve gerçekten etkilendik. Hızlı cevapları ve kaliteli hizmetleri sayesinde sorunumuz kısa sürede çözüldü.Teşekkürler!

Ümraniye internet arızasını yapan Ümraniye’deki elektrik tamircileri, bölgenin enerji ihtiyacını karşılamak için uzmanlıkla donanmıştır. Müşterilerin taleplerini karşılamak için hızlı ve etkili çözümler sunarlar. Elektrik tamircileri, geniş bir yelpazedeki elektrik sorunlarını çözebilecek yeteneklere sahiptir ve müşteri memnuniyetini en üst düzeye çıkarmak için çalışırlar