Hello friends, Today we are going to talk about try square which is the part of metrology. In which you will learn all aspects related to try square such as parts, types, checking accuracy methods, uses, etc.

What is Try Square?

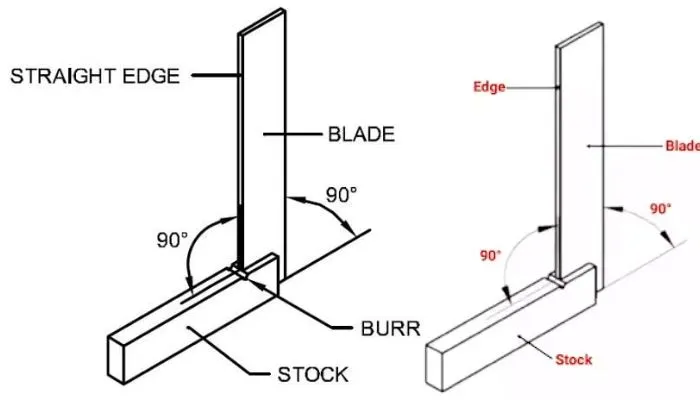

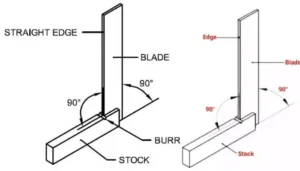

A try square is a measuring and marking tool used in woodworking, metalworking, and other trades to check the accuracy of right angles and to mark straight lines. It consists of two arms, a longer one called the blade and a shorter one called the stock, which meet at a right angle to each other. The try square is designed to help ensure that surfaces and edges are perpendicular to each other, forming precise right angles.

A try square is a measuring and marking tool used in woodworking and metalworking to check the accuracy of right angles and to mark straight lines. Here are the key components, types, grades, methods for checking accuracy, and common uses of a try square:

Parts of a Try Square

- Blade (Blade Edge): The long arm of the try square used for measuring and marking.

- Stock (Handle): The shorter arm perpendicular to the blade, forming a right angle.

- Stock Base: The bottom surface of the stock that rests against the workpiece.

Types of Try Squares

- Woodworking Try Square:

- Typically has a wooden stock.

- Used in woodworking for marking and checking right angles.

- Metalworking Try Square:

- Often has a metal stock, providing durability and stability.

- Commonly used in metalworking and machining applications.

- Combination Try Square:

- Features an additional spirit level or a 45-degree angle.

- Offers versatility for various tasks.

Grades of Try Squares

Try squares are available in different grades based on their accuracy and construction quality. Common grades include:

- Machinist Grade:

- High precision and accuracy.

- Suitable for demanding machining and metalworking applications.

- Carpenter Grade:

- Good accuracy for general woodworking tasks.

- May not meet the precision requirements of machining.

Checking Accuracy of a Try Square

- Edge Alignment: Place the try square against a straight edge or surface. The blade should align perfectly with the edge without any gaps or overlaps.

- 90-Degree Angle: Check the squareness by placing the try square against a true 90-degree corner or using a 90-degree reference. Ensure the blade and stock form a right angle.

- Measurement Consistency: Verify that the measurements on both sides of the blade are consistent and accurate.

Uses of Try Square

- Marking 90-Degree Angles: Primary use is for marking and checking right angles in woodworking and metalworking projects.

- Checking Squareness: Verifying the accuracy of corners and ensuring that surfaces are perpendicular.

- Measuring: Taking measurements in a precise and straight manner using the markings on the blade.

- Layout Work: Used in layout work to scribe straight lines and check the accuracy of other tools.

- Quality Control: Ensuring the precision and accuracy of machined or assembled components.

Remember that the accuracy and reliability of a try square are crucial for obtaining precise results in various applications. Regularly checking and maintaining the tool is essential for accurate work.

Read also: Are PET Bottles Safe for us and the environment?

In this topic, we’ve discussed What is try square, parts of try square, as well as their uses, precaution, etc.

I hope you like this post.

Thank You.